|

Anping Yanzhao Griddle Wire Mesh CO.LTD

|

Wrapped Wire Screen

| Price: | 100.0~150.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Welded wire wrapped screen is constructed by support rod and sieve rod.

Welded wire wrapped screen is constructed by support rod and sieve rod.

Material: low carbon steel wire, galvanized wire, and 302, 304, 304 L, 316, 316 L stainless steel wire and so on.

Application: welded wire wrapped screen can be widely used in oil, gas, water wells sand prevention, chemical, environmental protection industries, its position in the water treatment industry is particularly conspicuous, the collection of various water resources and the application of the most resin filter sieve and extensive.

Features:

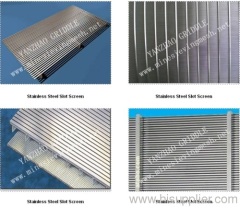

1. A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone.

2. A "V" shaped profile wire which avoids clogging and ensures an uninterrupted flow.

3. A uniform and efficient well development due to the continuous slot opening.

4. Ladder-like wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

5. Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

1. A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone.

2. A "V" shaped profile wire which avoids clogging and ensures an uninterrupted flow.

3. A uniform and efficient well development due to the continuous slot opening.

4. Ladder-like wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

5. Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

Specifications:

Model | Nom.Size | OD (mm) | ID (mm) | Rod Num | App.Weight (kg/m) |

TY27 | 3/4 | 38 | 32 | 20 | 1.3 |

TY33 | 1 | 41 | 35 | 22 | 1.5 |

TY48 | 1 1/2 | 56 | 50 | 26 | 4.0 |

TY60 | 2 3/8 | 75 | 62 | 22 | 5.3 |

TY73 | 2 7/8 | 88 | 75 | 26 | 6.0 |

TY89 | 3 1/2 | 105 | 92 | 30 | 7.0 |

TY102 | 4 | 118 | 105 | 32 | 7.5 |

TY114 | 4 1/2 | 131 | 118 | 38 | 9.0 |

TY127 | 5 | 143 | 130 | 40 | 10.0 |

TY140 | 5 1/2 | 156 | 143 | 44 | 11.0 |

TY168 | 6 5/8 | 185 | 172 | 54 | 13.0 |

TY178 | 7 | 195 | 182 | 58 | 14.5 |

TY194 | 7 5/8 | 201 | 198 | 62 | 16.0 |

TY219 | 8 5/8 | 236 | 223 | 70 | 18.0 |

TY244 | 9 5/8 | 263 | 250 | 78 | 21.0 |

TY273 | 10 3/4 | 291 | 278 | 88 | 23.5 |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Wire Screen

Paper Wrapped Wire

Black Wire Screen

Mine Wire Screen

Decorative Wire Screen

Wire Mesh Screen

More>>